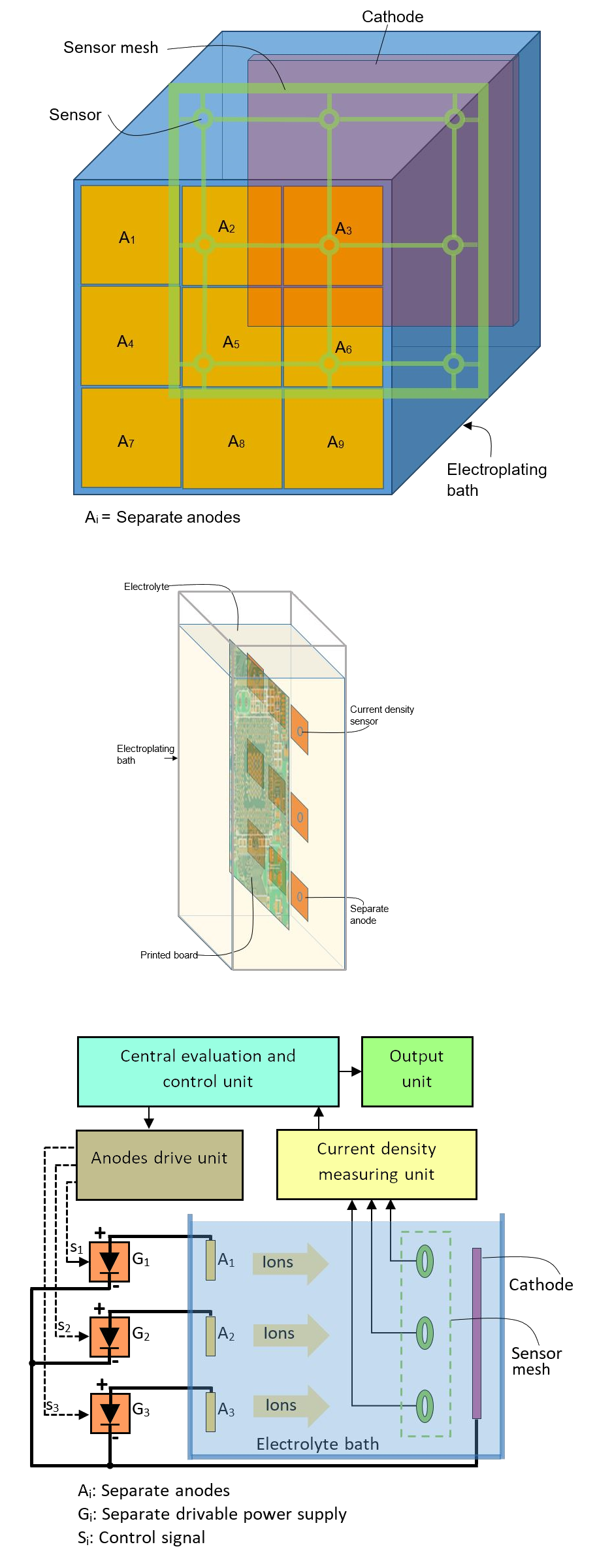

Within the project "Process technology for generating homogeneous layer thicknesses through sensor network and individually controllable current sources" - in German: "Verfahrenstechnik zur Erzeugung homogener Schichtdicken durch Sensornetz und einzeln ansteuerbare Stromquellen" (in short: VESAS), Engineering Office PhysiTronik takes on, several challenges among others development of processes and the special sensor meshes and control system.

The current densities measured by the sensor mesh are to be passed to the current density measuring unit, which then forwards them immediately to the central evaluation and control unit. If the measured current values are unequal, the voltages of the power supplies the responsible anodes will be changed until an equality of the current values is attained. The applied voltages of anode are controlled via the control signal of the power supply of the respective anode.

Moreover, an extension of the concept is possible to make 3-dimensional sensor mesh, whereby its application for curved and non-planar work pieces becomes possible. The VESAS system is also very suitable for automating coating of large work pieces!

The european patent EP3581685B1 is registered.